Process safety is not a separate role within a plant. It is a responsibility shared by every chemical engineer.

Start with These Articles

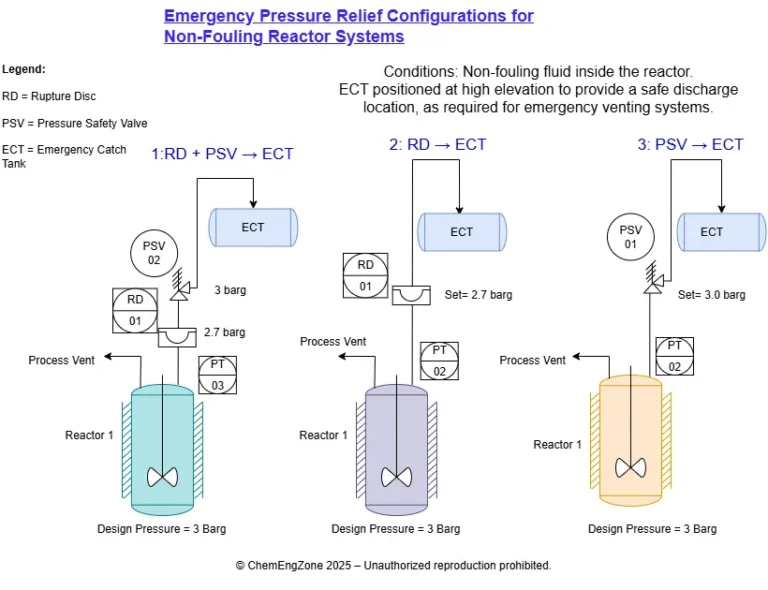

Pressure Safety Valve vs Rupture Disc: Key Differences

A practical engineering comparison with a real reactor example, covering PSV, rupture disc, and RD+PSV configurations used in chemical plants …

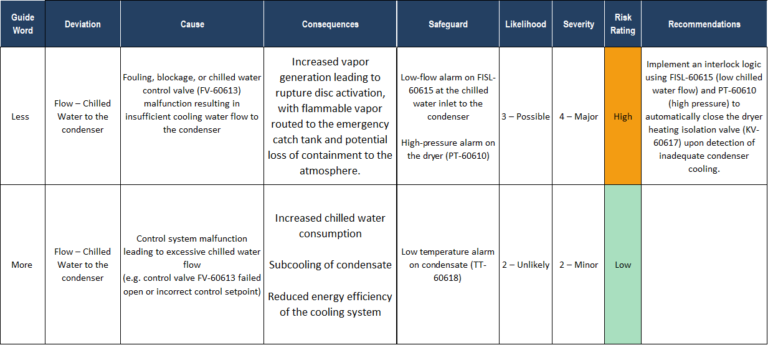

What Is HAZOP Analysis? Example and Template

A practical HAZOP analysis example showing how deviations, causes, consequences, safeguards, and risk are evaluated using a real worksheet …

Safety Interlocks: P&ID Example

Cryogenic VOC abatement systems are highly effective but face operational limits when CO₂ or water freezes at low temperatures. This …

📘 Process Safety Articles

Safety Management Framework

Hazard Identification & Risk Analysis

- What Is HAZOP Analysis? Example and Template

- HAZOP Example: Material Compatibility Failure

- LOPA & SIL: Practical Examples

Protection Layers & Safeguards

- Pressure Safety Valve vs Rupture Disc: Key Differences

- Rupture Disc Activation: Near Miss or PS Event

- Rupture Disc Installation: Where to Place It

- Safety Interlocks: P&ID Example

Equipment & Design-Related Hazards

- Vent Header Design: Safer Top Tie-In Layout

- Control Valve Leak and System Isolation

- Vacuum Tank Collapse: Hazards & Prevention

Hazardous Areas & Emission Risks

Fix the Concept – Engineering PDFs

Download concise technical summaries designed to reinforce the engineering principles behind hazard identification, risk analysis, and process safety decision-making.

Discover the PDFs in Fix the ConceptEngineering Updates & Technical Insights

Receive structured technical articles, practical engineering insights, and real industrial case analyses directly in your inbox. No noise. Only serious engineering content.