What Does a Chemical Engineer Do? Roles and Responsibilities

Before addressing the question of what a chemical engineer does, the article What Is Chemical Engineering and How It Shapes Everyday Life uses a concrete but straightforward real-world example to explain what chemical engineering is and how it appears in everyday industrial systems.

This article builds on the same visual framework, but shifts the focus from the discipline itself to the role of the chemical engineer within that system.

The objective is to move from what chemical engineering is to what a chemical engineer actually does, clarifying the responsibilities, technical decisions, and practical reasoning that define the profession in real industrial contexts.

Inside a Chemical Plant: A Real-World Engineering Example

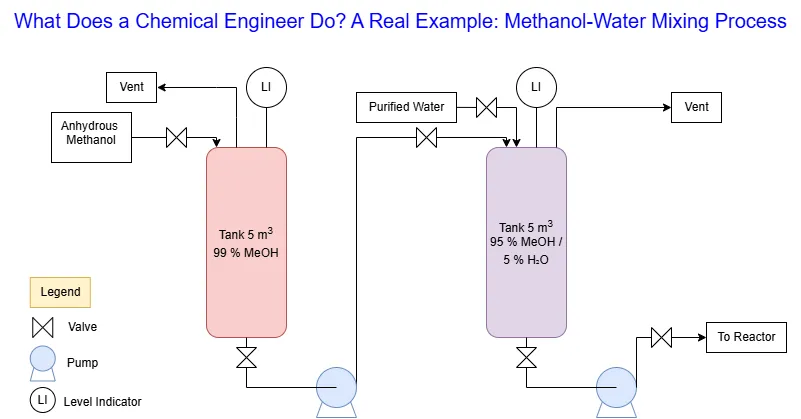

If we consider a typical section of a chemical plant, purified water and anhydrous methanol are stored in dedicated tanks.

Through a system of pumps, valves, and flow controllers, controlled amounts of each component are transferred into a third vessel to prepare a 95% methanol–5% water solution.

This mixture is then fed to a reactor as part of a larger chemical process.

At first sight, this setup looks simple: a few tanks, pumps, level transmitters, and pipelines. In reality, even such a “basic” system requires multiple engineering decisions:

- Process design: Which concentration and flow rates are required for the downstream reaction?

- Safety: How are vapors managed? Is proper venting or inerting in place?

- Instrumentation and control: How are levels, pressures, and flows measured and regulated?

- Operation and maintenance: What procedures guarantee continuous and reliable service?

This small example shows how chemical engineering goes beyond equipment layout. Even apparently simple systems demand the integration of safety, efficiency, and operability to ensure reliable plant performance.

Responsibilities within Chemical Engineering

Chemical engineering rarely involves a single role working in isolation. Even in relatively simple plant sections, multiple engineering disciplines contribute, each with a distinct responsibility.

Using the methanol–water mixing system as a reference, the following roles are typically involved in real industrial practice.

Process Engineer

The process engineer is responsible for defining how the process should operate from a technical standpoint. This includes defining process specifications and operating targets, sizing tanks, piping, and equipment based on fluid properties and operating conditions, and evaluating the impact of temperature, pressure, and residence time on process behavior. Normal operating conditions are established, and operability is assessed to ensure the system can be run safely and efficiently.

In this example, these responsibilities translate into defining the target mixture composition and the flow rates required by the downstream reactor.

Process Safety Engineer

The process safety engineer focuses on identifying hazards and preventing accidental scenarios. This role includes analyzing flammability risks, overpressure scenarios, and material compatibility, defining safeguards such as venting, inerting, or explosion protection, and leading or supporting Process Hazard Analyses such as HAZOP studies. Control and shutdown systems are also reviewed to ensure they meet safety requirements.

In this case, particular attention is given to methanol flammability and vapor management.

Project Engineer

The project engineer coordinates the practical implementation of the system. Responsibilities include managing equipment installation, piping and instrumentation works, schedule and budget control, procurement, and contractor coordination. Engineering documents are reviewed for compliance with plant standards, and the interface between design teams and site operations is managed during commissioning.

Maintenance Engineer

The maintenance engineer ensures long-term reliability and availability of the system. This includes evaluating equipment reliability and material compatibility, defining preventive maintenance plans and spare-parts strategies, investigating failures or abnormal conditions, and proposing corrective actions to improve safety and performance over time.

Applying Chemical Engineering Skills Across Industrial Processes

Chemical engineers play a central role in the design, optimization, and management of industrial processes. Their expertise spans multiple sectors, with responsibilities in plant operations, safety, and regulatory compliance.

Some real-world applications of these engineering skills include:

– Designing and operating distillation columns to separate crude oil into fuels and chemical products

– Optimizing heat exchangers and utilities to reduce energy consumption

– Scaling up formulations from laboratory development to industrial production

– Operating and controlling polymerization units for plastics manufacturing

– Designing and managing process safety systems in chemical and refining plants

– Performing HAZOP studies to identify hazards and improve safeguards

– Developing water and wastewater treatment processes to meet environmental limits

– Ensuring process validation and product consistency through engineering control

Interested in the range of professional roles in chemical engineering?

→ Explore Career Opportunities in Chemical Engineering

Conclusion

This example shows that the work of a chemical engineer is not defined by isolated calculations or individual pieces of equipment, but by the ability to integrate process design, safety, control, and operability into a coherent industrial system.

Engineering judgment, trade-off analysis, and coordination across disciplines are what turn process design into real industrial practice.

Ing. Ivet Miranda

⬆️ Back to TopOther Articles You May Find Useful

- Process Engineer: 2 Essential Field Skills

- Unit Operations for Chemical Engineers

- Fluid Dynamics Basics for Engineers

- Heat Transfer Basics for Engineers

- Chemical Engineering Principles Explained

- Bernoulli’s Principle: Equation & Applications

FAQ

What is the Job of a Chemical Engineer?

The job of a chemical engineer involves designing, developing, and improving industrial processes that transform raw materials into useful products. This includes ensuring safety, efficiency, and sustainability in areas such as pharmaceuticals, energy, food production, and environmental protection.

– Back to the full explanation

What are Chemical Engineer Responsabilities?

Chemical engineers work on everything from process design to safety and compliance.

Explore Responsabilities Here

Can chemical engineer work in food industry

Yes, chemical engineers can work in the food industry and are often highly valued for their skills in process design, quality control, and production optimization.

What chemical engineers do on a daily basis

The daily activities of a chemical engineer vary depending on the industry and role, but typically include a mix of technical, analytical, and collaborative tasks.

How many hours do chemical engineers work

Chemical engineers typically work full-time schedules, averaging 40 to 45 hours per week. However, actual working hours can vary depending on the industry, position, and whether the role is plant-based or office-based.

What do chemical engineers do on a daily basis

Chemical engineers design and optimize processes that involve fluids, heat, and reactions. Daily tasks include monitoring equipment, ensuring safety with hazardous chemicals, controlling pumps and valves, and collaborating with maintenance and operations teams.