Cryogenic Abatement in VOC Control

Cryogenic abatement systems are often perceived as robust and highly efficient solutions for VOC emission control.

In reality, they can become operationally fragile when trace components behave differently under cryogenic conditions.

One of the most critical examples is CO₂.

Harmless at ambient temperature, CO₂ can solidify below −78 °C, forming local blockages that restrict flow, reduce effective cross-section, and compromise system reliability.

This risk does not usually originate from the main process chemistry, but from residual air, inerting practices, and trace contaminants that enter the system unnoticed.

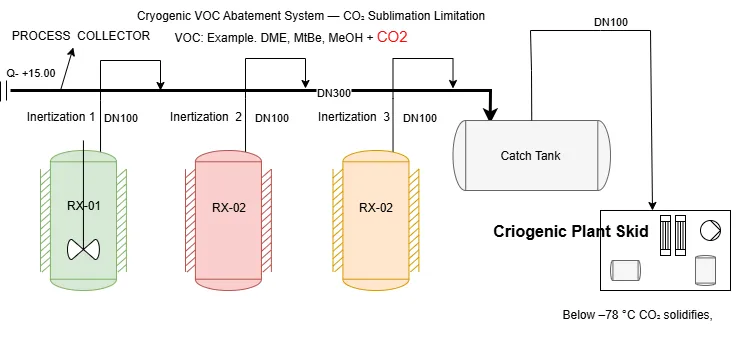

Figure 1 illustrates a typical cryogenic abatement layout, where vent gases from multiple reactors are routed to a cold section for solvent condensation — and where solidification risks must be explicitly considered during design and operation.

Why CO₂ Solidification Is an Operational Risk

Unlike many process upsets, CO₂ solidification does not result in an immediate, obvious failure.

Its impact is progressive and localized.

As dry ice forms at the coldest points of the system, such as valve internals, exchanger inlets, or local restrictions — the effective flow area is gradually reduced.

This leads to increased pressure drop, unstable operation, reduced removal efficiency, and in some cases complete blockage of the vent path.

From an operational standpoint, this is particularly critical.

Once solidification begins, corrective actions are extremely limited: the system must be taken offline and warmed up to restore functionality.

For this reason, CO₂ solidification represents a loss-of-operability scenario, rather than a conventional process deviation.

It challenges system availability and reliability, even when the main process parameters appear to be under control.

Impact of CO₂ on Cryogenic Abatement Performance

In cryogenic abatement systems, the presence of CO₂ does not only pose a risk of local blockages.

As solid CO₂ accumulates at cold spots, heat transfer efficiency deteriorates and pressure losses increase, limiting the system’s ability to reach and maintain the target abatement temperature.

When the required cryogenic temperature cannot be achieved, VOC condensation becomes incomplete.

Depending on the solvent mixture and emission limits, this can lead to reduced removal efficiency and, in some cases, atmospheric emissions exceeding permitted thresholds.

From an engineering perspective, this links CO₂ solidification directly to abatement performance and environmental compliance, not only to operability.

Typical Sources of CO₂ in Cryogenic Vent Streams

In many chemical plants, CO₂ present in vent streams does not originate from the core process chemistry.

Instead, it is often introduced indirectly through residual air displaced during nitrogen inerting, purging operations, and start-up or shutdown sequences.

During these phases, VOC concentrations are typically low or negligible, while the CO₂ naturally contained in air is still present.

When routed through a cryogenic abatement unit, this CO₂ becomes a limiting factor, despite the absence of significant solvent emissions.

Design Considerations for Inerting and Vent Routing

During inerting or air-removal phases, reactors and vessels may not contain solvents, and VOC emissions can be limited to trace levels.

In these conditions, routing vent streams through a cryogenic abatement unit may provide limited environmental benefit, while introducing a significant CO₂ load to the system.

From a design perspective, this raises the question of whether inerting-related vents should always be treated together with solvent-containing process vents.

In some installations, alternative vent routing during specific operating phases may be considered to reduce unnecessary CO₂ exposure of the cryogenic section.

Such approaches, however, require dedicated piping, clear operating procedures, and robust interlocks to prevent misrouting under solvent-containing conditions.

Their applicability is therefore highly plant-specific and must be evaluated case by case.

Conclusion

Cryogenic abatement units are highly effective tools for VOC emission control, but their performance strongly depends on the behaviour of trace components under cryogenic conditions.

CO₂ solidification represents a subtle but critical failure mode: it does not immediately trigger alarms, yet it progressively undermines operability, heat transfer efficiency, and ultimately VOC removal performance.

In many cases, the source of CO₂ is not the process chemistry itself, but operating phases such as inerting, purging, or start-up activities.

Recognizing these mechanisms during design and operation is essential to ensure that cryogenic abatement systems deliver the expected environmental performance without compromising plant reliability.

Ing. Ivet Miranda

⬆️ Back to TopCryogenic CO₂ Risk Quiz

During cryogenic VOC abatement, even small amounts of CO₂ are detected in the vent gas.

What is the main operational risk when the stream is cooled below –70 °C?

Other Articles You May Find Useful

• ATEX Zone Classification: Gas, Vapour & Mist

• What Is HAZOP Analysis? Example and Template

• Decarbonization: VSD Pump Level Control

• Vent Header Design: Safer Top Tie-In Layout

FAQ

What is cryogenic abatement in VOC emission control?

Cryogenic abatement is a VOC emission control technique based on cooling vent gases to very low temperatures, allowing volatile organic compounds to condense and be removed from the gas stream.

Its effectiveness depends on maintaining the required cryogenic temperature and stable flow conditions.

Why can CO₂ be a problem in cryogenic VOC abatement systems?

Although CO₂ is harmless at ambient conditions, it can solidify below −78 °C. In cryogenic abatement units, this may lead to dry ice formation at cold spots, causing flow restrictions, pressure losses, and reduced system reliability.

Where can CO₂ in cryogenic vent streams originate from?

In cryogenic VOC abatement systems, CO₂ may originate from different sources depending on the plant configuration and operating phase.

In some cases, CO₂ is generated by the process chemistry itself. In others, it can be introduced indirectly through residual air during nitrogen inerting, purging operations, or start-up and shutdown conditions, when air ingress is more likely.