4 Safety Management System Pillars in a Chemical Plant

The 4 pillars of a Safety Management System (SMS) define how safety is structured, applied, and sustained across industrial operations — turning safety from a concept into a working system.

When applied correctly, SMS works as an integrated part of daily operations, aligned with both technical and organizational goals.

To understand how this framework operates, it’s essential to explore the four fundamental pillars: safety policy, risk management, safety assurance, and safety promotion & culture.

These components are not just theoretical—they serve as practical tools that guide design, implementation, monitoring, and continuous improvement across all departments.

In this article, we’ll explore how these pillars were applied in a real case: the installation of a 37% hydrochloric acid tank. The project included hazard analysis (HAZOP), Management of Change (MoC), targeted training, and coordinated actions between teams.

What Makes a Safety Management System Effective?

A Safety Management System is only effective when its core principles are fully integrated into daily operations — and when people at all levels are truly committed to safety.

Download the FREE PDF – 4 Pillars of SMS

Get a clear infographic showing the 4 fundamental pillars of a Safety Management System:

Safety Policy, Risk Management, Safety Assurance, and Safety Culture.

- Turns risk awareness into concrete action

It’s not enough to identify hazards — that awareness must lead to operational decisions, preventive measures, procedures, and behaviors that actually reduce risk in the field.

- Engages all departments, not just safety experts

Safety isn’t just the HSE team’s job. It requires active involvement from operations, maintenance, engineering, and management to become fully integrated into daily workflows.

- Makes training and communication part of the routine

Training and communication shouldn’t be reserved for special occasions — they need to become part of everyday practice through regular briefings, updates, and open dialogue.

- Uses risk assessment to drive preventive actions

Transforms awareness into procedures, preventive measures, and safe behaviors that effectively reduce risk in operations.

- Is driven by leadership and reinforced by culture

No system works without leadership commitment and a safety culture where everyone — from top management to frontline staff — feels responsible for keeping people and processes safe.

Pillar 1: Safety Policy

Every Safety Management System starts with a clear safety policy. But what does that really mean?

A Safety Policy isn’t just a document for EHS compliance, framed in the EHS director’s office. It’s a practical tool that defines how safety decisions are made, who is accountable, and how priorities are communicated across the organization.

A credible policy includes:

- Clear and measurable objectives – Goals such as “Zero Incidents” must be supported by indicators, timelines, and regular tracking.

- Risk-based decision-making – Safety meetings, audits, and actions should follow risk assessments, not generic checklists.

- Visible leadership involvement – Senior leaders should actively participate in safety reviews, resource planning, and communication.

- Employee protection and engagement – Workers must be free to report concerns and act on safety issues without fear of retaliation.

When the policy is actively implemented and supported by leadership, it aligns all departments—production, maintenance, engineering, quality—under a unified safety vision. Without it, safety tools risk becoming routine exercises, disconnected from real improvement.

Pillar 2: Risk Management

Risk management is the operational core of any SMS.

You can’t talk about safety without addressing real hazards in the plant, evaluating them methodically, and making informed decisions.

This second pillar of the Safety Management System relies on practical tools: HAZOP studies, process deviation analysis, MoC (Management of Change), and cross-functional collaboration.

Field Example – Transfer Operation from 37% Hydrochloric Acid Tank

Hydrochloric acid (HCl) in 32–37% aqueous solution is classified as corrosive (Skin Corr. 1B – H314, Eye Dam. 1 – H318) and irritating to the respiratory system (STOT SE 3 – H335) according to its safety data sheet (SDS), CAS Number: 7647-01-0.

However, it is always recommended to verify the specific hazard statements in the SDS provided by the manufacturer.

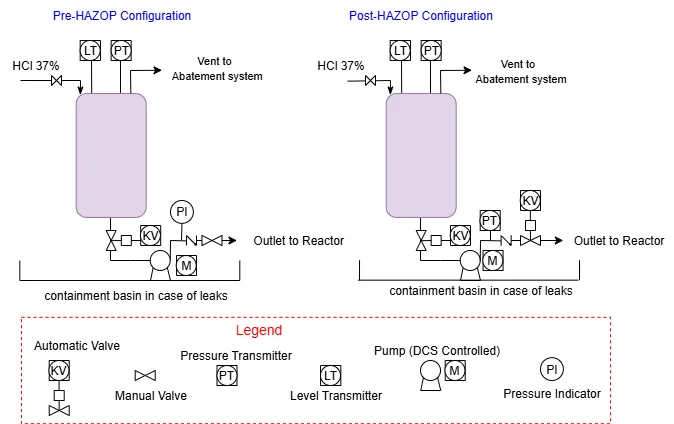

The picture shows a safety improvement applied to a chemical transfer system, comparing the configuration before and after the HAZOP analysis, as an example of a risk assessment element within a Safety Management System (SMS).

- Before HAZOP:

A 37% hydrochloric acid (HCl) solution was stored in a dedicated tank equipped with a level transmitter (LT) and a pressure transmitter (PT), with vapors routed to the abatement system.

The transfer to the reactor was performed via a pump managed by DCS and a manual valve, with a local pressure indicator (PI) installed downstream of the pump. Bottom tank valve DCS connected.

A check valve was installed on the pump discharge line to prevent backflow in case of shutdown or abnormal conditions.

The transfer operation of the HCl solution required manual access by the operator into the containment basin to open the pump discharge valve.

This configuration — similar to that implemented for other tanks containing flammable substances — exposed the operator to a direct risk of exposure to hydrochloric acid vapors, which are corrosive and can irritate the respiratory tract, particularly in the event of valve leakage or pump failure.

- After HAZOP:

Following the process review and detailed examination of the P&ID during the HAZOP study, several critical deviations were identified at the transfer node between the HCl storage tank and the reactor.

Among the main concerns were the risks associated with manual pump operation, potential valve or line leaks, and the lack of interlocks under abnormal pressure conditions.

To improve safety, an automatic valve (KV) was installed upstream of the pump and is now controlled via the Distributed Control System (DCS).

Additionally, a second pressure transmitter and a downstream automated block valve were added.

These new components are interlocked with the system to prevent product transfer under abnormal pressure conditions.

The risk assessment also revealed that the correct start-up sequence of the pump was essential to prevent malfunctions and ensure safe operation.

Specifically, opening the bottom valve first, then the discharge valve, and finally starting the pump allowed the suction line to be properly filled with liquid.

This avoided dry running of the pump — a condition that could otherwise lead to cavitation, mechanical damage, and potential release of HCL 37% solution due to abnormal operating conditions.

Conversely, starting the pump without first filling the suction line increased the risk of malfunction and exposure to hazardous substances.

The updated configuration ensures that the transfer process is now fully automated and continuously monitored, significantly reducing operator exposure and the likelihood of overpressure or vapor release. The containment basin remains in place for spill management.

This upgrade marks a shift from manual to automated control, enhancing overall safety for both personnel and the environment.

The SMS risk-management workflow became the project’s spine:

- MoC launch – A well-structured Management of Change (MoC) process was applied, requiring a formal description of the proposed modification — in this case, the installation of a new HCl storage tank.

- Preliminary hazard study – maintenance, instrumentation, operations, process safety, electrical and QA map worst-case scenarios.

- Full HAZOP on the P&IDs – startup, shutdown and abnormal modes included.

- Multidisciplinary brainstorming – operators, engineers and EHS challenge “what-ifs” not obvious from the drawings.

- Safeguard design – A new automatic valve and pressure transmitter were interlocked with each other. A new pump startup procedure was also implemented.

Safety Begins at the Design Stage

The best approach is to integrate safety from the design phase.

Example. In one project, a suction line connected a pump to a tanker. The design had no breakpoints or space to install a filter. After startup, the incoming product was found to be contaminated. That missing filter caused operational issues, quality risks, and potential hazards.

Retrofitting the filter required cutting and rebuilding the entire suction line—an expensive, slow, and disruptive intervention. A design-phase risk assessment could have identified the hazard early and prevented the problem entirely.

Designing with safety in mind not only prevents incidents, but also improves efficiency, stability, and long-term operability.

Pillar 3: Safety Assurance

A Safety Management System can’t thrive without a way to measure, verify and improve. That’s the job of SMS safety assurance: tracking performance over time and turning data into prevention.

In practice, teams focus on:

- leading & lagging indicators,

- systematic near-miss collection and analysis,

- internal audits and technical inspections,

- prompt follow-up on corrective actions.

What exactly is a near miss?

A near miss is an event that could have caused harm but didn’t—often thanks to quick reactions or pure luck. Think of a pinhole leak caught early, or a power dip managed before a reactor tripped. These “almost accidents” are free lessons; ignore them and you squander early-warning signals.

Field insight – During a routine inspection, a small leak was detected on a pump transferring flammable solvents from a storage tank. Maintenance repaired it immediately, but the team still carried out a root cause analysis within 24 hours.

It emerged that although the pump was included in a preventive maintenance plan, it showed signs of accelerated wear: the inspection interval set when the equipment was new was no longer adequate.

As a result, the procedure was updated and the time between scheduled maintenance checks was reduced.

By closing the loop between detection and action, safety assurance cements the other safety management system pillars and shifts the mindset from reactive to proactive safety.

Audits and external verification

Another key part of safety assurance is conducting safety audits.

While internal audits are useful, one particularly effective strategy is to bring in external companies specialized in HSE auditing.

Being audited by an independent third party allows you to:

- verify compliance with national and international standards,

- gain professional insights into areas of improvement,

- and demonstrate a genuine, measurable commitment to safety.

In short, it’s a powerful way to prove that safety isn’t just a statement — it’s a system that is tested, challenged, and continuously improved.

Pillar 4: Safety Promotion & Culture

Safety can’t be sustained by procedures alone; it has to turn into a shared mindset. This final safety management system pillar builds an environment where safety shapes how people think, act and communicate—especially when no one is watching.

Safety is everyone’s responsibility

In high-risk industries like chemicals and pharmaceuticals, major incidents — from Bhopal to Texas City, from Seveso to Port Neches — highlight how essential it is to have a well-structured Safety Management System.

Investigations by the U.S. Chemical Safety Board and other agencies show how a lack of clear procedures, risk control, and leadership alignment can turn small oversights into catastrophic failures.

Organizations with a strong safety culture invest in education, encourage reporting and reward constructive doubt every time the plant changes.

Communication, training and example

Promoting safety means talking about it daily—in meetings, toolbox talks, dashboards and informal chats. It also means:

- Offering accessible, role-specific training

- Recognizing proactive behaviours

- Encouraging team-wide learning

- Using real incidents or near-misses as lessons

Safety slogans – turning messages into habits

- Stop and think before you act.

- You are the first safety barrier.

- Report it before it becomes a problem.

- Safety is a decision—make it every day.

- Small signs, big consequences. Stay alert.

- No task is so urgent that safety can be ignored.

Recycle these everywhere—email signatures, dashboards, digital signage. Repetition forges a common language and turns safety from checklist to reflex.

Culture is the mortar binding the other SMS pillars. Without it, even the best policy, risk tools and assurance metrics crumble under routine pressure. Cultivate it daily—through talk, training, recognition and example—and safety will outlast any audit.

SMS and Regulatory Framework

A Safety Management System (SMS) is more than best practice—in many industries it is a legal requirement that obliges companies to identify, control and continuously reduce risk.

Regional Legal Requirements

• Europe – Seveso III Directive 2012/18/EU mandates a formal SMS for every major-accident-hazard establishment, covering process safety, emergency planning and training.

• United States – OSHA 29 CFR 1910.119 Process Safety Management lists 14 compulsory elements of a compliant safety programme.

• United Kingdom – COMAH Regulations 2015 implement Seveso principles to prevent and mitigate major chemical accidents.

International Standards

• IEC 61511 Functional Safety – Safety Instrumented Systems sets lifecycle requirements for SIS in the process sector.

• API RP 754 Process-Safety Performance Indicators defines Tier 1-to-Tier 4 metrics used worldwide.

• ISO 45001 Occupational Health & Safety Management Systems is the global benchmark that replaced OHSAS 18001.

TIP FOR TRAINING AND CASE STUDIES

The U.S. Chemical Safety Board publishes investigation reports and animations that are excellent material for workshops and toolbox talks.

Thanks for reading.

Ing. Ivet Miranda

Looking to Build a Stronger Foundation in Chemical Engineering? Start Here:

- What Is Distillation and How It Works in Real Industrial Processes

- Chemical Engineering Guide: 14 Useful Topics for Beginners

- Unit Operations: A Practical Introduction for Engineers

- 5 Key Differences: Rupture Disc vs Relief Safety Valve

- What Does a Chemical Engineer Do?

- Thermodynamics for Engineers

- What is the Process of distilling Water, Alcohol and Oil?

FAQ

What are the four pillars of a Safety Management System?

Safety Policy, Risk Management, Safety Assurance, and Safety Promotion & Culture. These terms are also used in aviation. In process industries, they match the mandatory chapters of Seveso III and OSHA PSM.

Is a Safety Management System mandatory under the Seveso III Directive?

Yes: every major accident hazard establishment must demonstrate a formal SMS compliant with Annex III of Directive 2012/18/EU.

How does SMS differ from OSHA Process Safety Management?

SMS covers the full cycle: risk–operations–culture. OSHA PSM details 14 technical and documentation elements. In a U.S. plant, SMS encompasses PSM.

What is a near miss in safety assurance?

An event that could have caused damage but didn’t. Analyzing it helps prevent real incidents at minimal cost.

How often should HAZOP studies be repeated?

Generally every 5 years or after each significant modification (MoC), based on CCPS and OSHA guidelines.

Can ISO 45001 replace a process-safety SMS?

No: ISO 45001 covers occupational health and safety. A process-specific standard such as IEC 61511 or API RP 754 is still needed.

What’s the best way to promote safety culture on shift?

10–15 minute micro-trainings, sharing near misses at the start of the shift, and visual slogans on digital dashboards.

Which standard governs Safety Instrumented Systems?

IEC 61511 (or ANSI/ISA 84 in the U.S.) defines the full lifecycle for SIS in the process sector.