Decarbonization Through Process Control Decisions

Decarbonization in industrial plants is often discussed in terms of high-level strategies, energy transition targets, or corporate sustainability plans. In practice, a substantial part of the impact originates from detailed engineering decisions made during process and control design.

Equipment operation and control philosophy play a central role in this context. Pump selection, control strategies, and operating margins directly influence energy consumption, process stability, and overall plant efficiency.

This article focuses on a practical example: the use of a variable-speed centrifugal pump for level control in a downstream process step. Starting from a simple process configuration, it illustrates how a standard control choice can reduce unnecessary energy consumption, improve operability, and contribute in a tangible way to industrial decarbonization.

Variable-speed pumps and energy behavior

Variable-speed control is effective only when the process allows it.

In this separation step, flow demand varies and transfer is not time-critical, making speed modulation both practical and beneficial.

In other services requiring constant or time-constrained flow, speed control may offer little advantage.

Energy savings therefore arise as a consequence of process flexibility, not as a generic feature of variable-speed drives.

The impact of these principles becomes clear when applied to a specific process configuration. The following example illustrates how a simple control choice during a separation step directly affects energy consumption.

Pump Speed Control During the Separation Phase

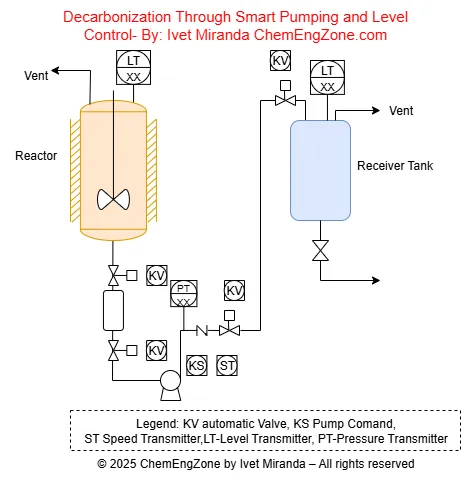

In the P&ID shown above, the separation phase is managed through a variable-speed pump whose rotational speed is adjusted based on the level conditions in the reactor and in the receiver.

During normal operation, the pump does not run at a fixed speed. Instead, its speed is continuously adapted to the actual inventory levels in the two vessels. When the level difference is small, the pump operates at reduced speed; as transfer demand increases, speed is raised accordingly. The control signal is therefore driven by process requirements rather than by a predefined maximum flow rate.

This control logic has a direct impact on energy consumption. By modulating pump speed instead of throttling flow with a valve, the system avoids dissipating excess energy as pressure losses. As a result, the electrical power absorbed by the motor decreases whenever full flow is not required, which is the most common operating condition during separation and transfer steps.

From a decarbonization perspective, this approach translates into lower electricity demand over the operating cycle. Energy is supplied only when and where it is needed, reducing avoidable losses associated with constant-speed operation. The resulting reduction in power consumption directly contributes to lowering the carbon footprint of the unit operation without modifying the process chemistry or layout.

This example shows how decarbonization in industrial plants is often achieved through control and operational choices embedded in everyday engineering design. The benefit does not come from advanced equipment alone, but from how process signals are used to align energy input with real process demand.

Conclusion

This example shows how decarbonization in industrial plants is often the result of practical engineering choices rather than major process changes. Controlling a pump through variable speed, based on actual process levels, allows energy input to follow real demand instead of being dissipated through throttling.

The benefit is not limited to reduced power consumption. Improved process stability, smoother operation, and lower mechanical stress are direct consequences of a control strategy that acts at the source of energy transfer. When applied systematically, these decisions lead to measurable reductions in energy use and associated emissions.

Ing. Ivet Miranda

⬆️ Back to TopPump Control and Decarbonization – Quiz

In the separation example discussed in this article, what is the main reason why variable-speed pump control reduces energy consumption?

Other Articles You May Find Useful

• Fluid Dynamics Basics for Engineers

• Bernoulli’s Principle: Equation & Applications

• What Is HAZOP Analysis? Example and Template

• VOC Emission Control: CO₂ Solidification Risks

FAQ

How do Variable Speed Drive (VSD) pumps contribute to decarbonization?

VSD pumps reduce energy consumption by adjusting motor speed to the actual process demand, avoiding waste from throttling valves. Lower energy use means fewer indirect CO₂ emissions.

Why is decarbonization important for industry?

Because industrial plants are major energy consumers. Improving energy efficiency and reducing CO₂ emissions not only supports global climate targets but also lowers operating costs and improves competitiveness.

What role do chemical engineers play in decarbonization?

Chemical engineers design, optimize, and operate processes. Their decisions—from pump selection to heat integration—directly influence energy use and emissions, making them central to decarbonization strategies.

What are some practical examples of decarbonization in plants?

Examples include installing variable speed drive pumps, using heat exchangers for energy recovery, switching to cleaner fuels, applying process intensification, and improving monitoring through digital control systems.