What Is Chemical Engineering?

Chemical engineering is the branch of engineering that deals with transforming matter and energy through physical and chemical processes.

It means designing, managing, and optimizing plants and operations that allow us to produce useful products on an industrial scale, like pharmaceuticals, fuels, materials, and chemicals.

Chemical engineering studies can be challenging, but the discipline is highly rewarding.

Its principles are applied in an enormous variety of products, from medicines and fuels to food, materials, and everyday consumer goods.

This breadth of applications makes chemical engineering an attractive choice for anyone seeking a career with strong prospects and long-term opportunities.

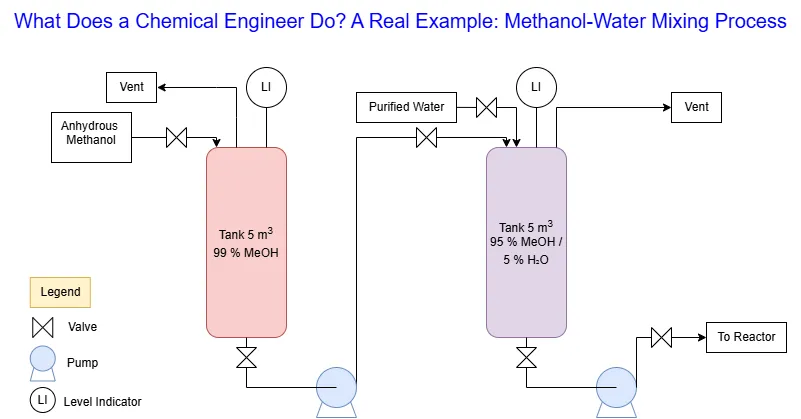

To illustrate what chemical engineering deals with, let us consider a simple yet realistic case: transferring methanol from one storage tank to another containing water, in order to prepare a diluted stream for use in a downstream unit.

Even in this apparently basic operation, several core aspects of chemical engineering emerge:

- Thermodynamics allows prediction of the properties of the methanol–water mixture, including density, boiling point, and phase behavior.

- Fluid dynamics determines the pressure drop along the transfer line, accounting for pipe length, fittings, and diameter.

- Mass balance defines the methanol volume required to achieve the desired concentration in the receiving tank.

- Materials selection ensures that pipes, seals, and gaskets are compatible with methanol and the operating environment.

- Process safety principles require safeguards against pump damage (e.g., dry running) and protection of personnel in case of leaks.

This example demonstrates how this discipline extends beyond laboratory chemistry: it integrates scientific knowledge with engineering judgment to deliver safe, efficient, and reliable operations at scale.

In industrial environments, these decisions must also account for process safety and risk management, as shown in 4 Safety Management System Pillars in a Chemical Plant.

Chemical Engineering vs Chemistry

Chemical engineering as a discipline differs fundamentally from chemistry, even if at first glance they may look similar.

From turning seawater into drinking water to producing life-saving vaccines, chemical engineers apply science to solve some of the world’s most critical challenges.

Chemistry focuses on the study of substances, their reactions, and the behavior of matter, with the primary goal of understanding how atoms and molecules interact under different conditions.

Chemical engineering, instead, applies this scientific knowledge to large-scale industrial processes. It blends physical and chemical principles with engineering practice to design, control, and optimize safe and efficient systems.

This transition — from understanding matter to transforming it into valuable products — defines chemical engineering as an applied discipline with direct industrial and societal impact.

Common Equipment

Some of the most common process equipment are those that enable physical and chemical transformations on an industrial scale.

Typical equipment includes pumps, which transfer fluids through the system, reactors, where chemical reactions are carried out, tanks, used for storing raw materials or finished products, and dryers, which remove moisture from solids.

Other key equipment comprises distillation columns for separating mixtures by boiling point, heat exchangers for transferring thermal energy between process streams, and separation devices such as filters and centrifuges.

Each piece of equipment plays a critical role in ensuring that processes operate efficiently and within safe design limits.

What Are Unit Operations?

Some of the foundational concepts in chemical engineering revolve around Unit Operations, the essential steps used to design, analyze, and control industrial processes.

These operations describe the physical transformations that occur during manufacturing and are applied across a wide range of sectors, including pharmaceuticals, petrochemicals, food processing, and environmental engineering.

Degree Structure

A chemical engineering degree typically spans 3 to 5 years, depending on the country and academic framework.

- In many European countries such as Italy, Spain, and Germany, the program is structured as a 3-year bachelor’s degree followed by a 2-year master’s degree.

- In the UK and France, universities often offer integrated master’s programs, lasting 4 to 5 years in a single track.

- In the United States, the most common path is a 4-year bachelor’s degree, which already qualifies graduates for most entry-level positions. Many students later pursue a master’s to deepen expertise or specialize in a particular sector.

The curriculum is designed to provide a solid foundation in engineering principles applied to physical and chemical processes, while also developing problem-solving and analytical skills.

Core Subjects

Depending on the university, students may also benefit from optional internships, international exchange programs, or online chemical engineering courses. These opportunities allow graduates to tailor their learning path toward R&D, industrial leadership, or further academic specialization.

A structured overview of these disciplines is presented in Chemical Engineering Core Disciplines – A Practical Overview, where each area is discussed from a practical engineering perspective.

Value of a Master’s

Deciding whether to pursue a Master’s after completing a bachelor’s degree is more than an academic choice.

Recruiters often see it not only as an additional qualification, but also as evidence of determination, proof that someone chose to go beyond the standard university path, accepting the effort of further study to keep improving.

This persistence is valued alongside the technical depth that a Master’s provides, and it can play strongly in a candidate’s favor.

A Master’s allows students to specialize in areas such as process optimization, sustainable technologies, pharmaceuticals, or advanced materials. While bachelor programs provide a broad foundation, the Master’s adds the depth required for technical leadership, research, or consultancy roles.

Entry-Level Jobs

Job titles do not always indicate the level of seniority. For example, it is common for graduates to begin their careers with titles such as Process Engineer or EHS Engineer, even without the “Junior” designation.

In many organizations, particularly in highly regulated sectors such as pharmaceuticals or energy, the title remains unchanged while responsibilities expand over time.

What truly differentiates entry-level positions from more advanced roles is the scope of work, level of autonomy, and whether the career path develops toward technical specialization or management.

Typical entry-level positions for chemical engineers include:

- Process Engineer – supports production activities, process optimization, and troubleshooting.

- EHS Engineer – assists in ensuring compliance with environmental, health, and safety regulations.

- Quality Control Analyst – performs laboratory tests and monitors product quality.

- Validation Specialist – contributes to process validation, qualification protocols, and documentation.

- Production Trainee – gains direct experience in plant operations and production management.

- Lab Process Technician – provides support in small-scale testing, data collection, and reporting.

Such roles are found across sectors including pharmaceuticals, food processing, energy, and manufacturing. While the titles may vary between companies, these positions represent the foundation of a chemical engineering career, combining structured learning with significant responsibility in real industrial environments.

To explore the topic further, see this article What Does a Chemical Engineer Do?

These activities translate into a wide range of professional roles across industries, which are explored in more detail in Career Opportunities in Chemical Engineering.

The Importance of Internships

Internships are a crucial bridge between academic study and professional practice. They provide hands-on training in industrial environments, allowing students to apply theory to real equipment, gain familiarity with process operations, and build both technical and digital skills.

Key benefits include exposure to large-scale processes, development of competencies such as simulation software, and the chance to expand a professional network.

For many companies, internships are part of recruitment pipelines, with strong performers often receiving job offers.

In universities with industry partnerships, internships may be integrated into the curriculum, while elsewhere students secure placements independently.

Beyond technical learning, these experiences help clarify personal interests, whether in operations, modeling, safety, or quality, and guide future career choices.

Where to Find Chemical Engineering Internships

Identifying the right internship requires a proactive and structured approach. Some of the most effective channels include:

- University Career Services – Many chemical engineering departments maintain partnerships with industrial companies and regularly share internship announcements through dedicated career offices or faculty contacts.

- Professional Platforms – Online job portals such as LinkedIn, Glassdoor, and Indeed frequently list internship opportunities. In addition, regional platforms or industry-specific websites can provide relevant postings tailored to your area.

- Direct Applications – Contacting companies directly remains an effective strategy. Visiting the career sections of corporate websites often reveals internship programs or open applications. Even when no positions are explicitly advertised, firms in sectors such as chemical manufacturing, pharmaceuticals, food processing, and environmental engineering may consider motivated candidates.

- Professional Associations – Organizations like AIChE or national engineering societies often provide internship listings, networking events, and career resources for students.

A well-planned internship search should combine these approaches, balancing formal applications with networking and direct engagement with industry.

Average Pay for Chemical Engineers

Among engineering disciplines, chemical engineers consistently rank among the highest earners. Compensation levels vary widely depending on country, sector, and seniority.

Italy

Chemical engineers in Italy are usually hired under national collective labor agreements (CCNL), especially in the chemical and pharmaceutical industries. Approximate gross annual salaries are:

- Entry-level (neolaureati): €25,000–€32,000

- Mid-level (5–10 years): €35,000–€50,000

- Senior/Managerial roles: €55,000–€80,000+

Multinational companies, particularly in Northern Italy and in energy or pharmaceutical sectors, often offer higher compensation.

United States

According to the U.S. Bureau of Labor Statistics, chemical engineering is one of the top-paying engineering fields:

- Entry-level: $68,000–$80,000 per year

- Mid-career: $90,000–$110,000 per year

- Senior/Specialist roles: $120,000–$150,000+

Industries such as pharmaceuticals, oil & gas, and battery technology are among the most competitive.

International Outlook

- Germany: €50,000–€70,000 (early career)

- United Kingdom: £28,000–£35,000 (entry-level), rising to £60,000+ with experience

- Switzerland: among the highest in Europe, with averages above €80,000

- India: ₹400,000–₹800,000 for new graduates, with strong growth in pharma and petrochemicals

Additional Benefits

Beyond base salaries, many employers offer:

- Performance-based bonuses

- Relocation and housing allowances (especially for expatriates)

- Travel benefits and international assignments

- Access to training programs and certifications

Conclusion

Chemical engineering is not defined by a single industry, job title, or piece of equipment. It is defined by the ability to understand how systems behave, to anticipate how they may fail, and to design processes that continue to operate safely and reliably at scale.

From foundational principles to real industrial applications, chemical engineering remains a discipline centered on decision-making, responsibility, and the transformation of scientific knowledge into practical solutions.

Ing. Ivet Miranda

⬆️ Back to TopChemical Engineering Quiz

What primarily distinguishes chemical engineering from chemistry?

Other Articles You May Find Useful

- First Law of Thermodynamics and Joule Experiment

- Second Law of Thermodynamics: PM 2nd Kind

- Fluid Dynamics Basics for Engineers

- Bernoulli’s Principle: Equation & Applications

- Heat Transfer Basics for Engineers

- Process Engineer: 2 Essential Field Skills

FAQ

What Can You Do With a Chemical Engineering Degree?

You can work in industries like energy, pharmaceuticals, food, environment, or finance—doing anything from process design and R&D to sustainability, project management, or data analysis.

Is Chemical Engineering a good major?

Yes — it’s a valuable and versatile STEM degree that opens doors to high-demand fields like energy, pharma, environment, and materials, while building strong problem-solving and interdisciplinary skills.

Why is Chemical Engineering important?

Because it has a major impact on people’s lives — from producing life-saving medicines and clean water to developing sustainable energy and safer industrial processes. It transforms science into practical solutions that shape the world around us.

Is Chemical Engineering dangerous?

Not when proper safety measures are followed. While it may involve working with hazardous substances, chemical engineers are trained to design safe systems, conduct risk assessments (like HAZOP), and apply strict safety protocols. Most work takes place in controlled environments such as labs, offices, or monitored plants.

Is Chemical Engineering a bachelor of science?

Yes, it’s usually offered as a B.Sc. degree, combining chemistry, physics, math, and engineering subjects like thermodynamics and process control.

Is Chemical Engineering hard?

Yes, it’s challenging due to advanced math, chemistry, and system design—but it’s also rewarding and highly valued in industry.

Why study chemical engineering

It offers global career opportunities, strong salaries, and real-world impact—solving challenges in energy, sustainability, and production through science and engineering.