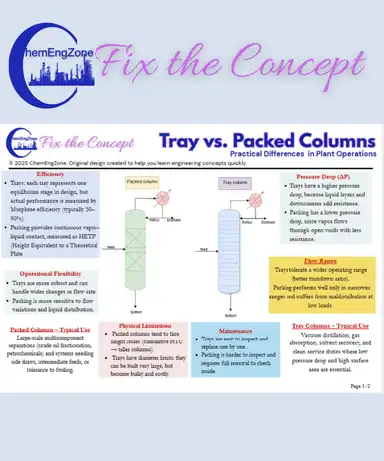

Trays Column vs Packed Column: Key Differences in Separation Operations

Practical overview of design, flexibility, and separation efficiency

Get the Free PDF – Tray vs. Packed Columns

A practical engineering comparison between tray and packed columns, focused on real plant operation. The PDF highlights key differences in efficiency, pressure drop, operating range, maintenance, and typical industrial applications to support informed design choices.

🔗 Useful External Links

AIChE – Chemical Engineering Progress (CEP)

Monthly journal by the American Institute of Chemical Engineers, featuring best practices in process design, optimization, and plant operation.

OSHA – Process Safety Management Guidelines

Official U.S. resource outlining key safety requirements for chemical and industrial plants.

Chemical Engineering Magazine (ChemEngOnline)

Leading publication covering industrial case studies, plant optimization, and process technologies.

Engineering Toolbox

Comprehensive database with thermodynamic properties, process diagrams, and equipment data for engineers.

Perry’s Chemical Engineers’ Handbook – McGraw Hill

The standard reference for chemical and process engineers worldwide, covering theory, design, and safety.

Other Articles You May Find Useful

- Tray Efficiency: Improve Column Performance

- Distillation Process: Key Principles and Equipment

- Heat Transfer Basics for Engineers

- Work in Thermodynamics. PV Diagrams

- Control Valve Leakage: Often Used Upstream

- What Is Chemical Engineering and How It Shapes Everyday Life

- Unit Operations for Chemical Engineers

FAQ

When should I use trays instead of packing?

Trays are chosen for large-scale separations, side draws, multiple feeds, or when fouling is expected, because they are easier to clean and more robust.

Why do packed columns have lower pressure drop?

Because vapor flows through open voids in the packing, with minimal resistance, making them ideal for vacuum or energy-sensitive operations.

How is efficiency measured for trays and packing?

Tray performance is expressed through Murphree efficiency, while packing efficiency is compared using HETP (Height Equivalent to a Theoretical Plate).

Which system handles flow variations better?

Trays can tolerate wider turndown ratios. Packing works well in steady ranges but suffers from maldistribution if the liquid load drops too low.

What are the main maintenance differences?

Trays can be inspected and replaced individually. Packed beds usually require full removal to check or clean, making them less practical with dirty services.