FREE PDF 4 Pillars of SMS

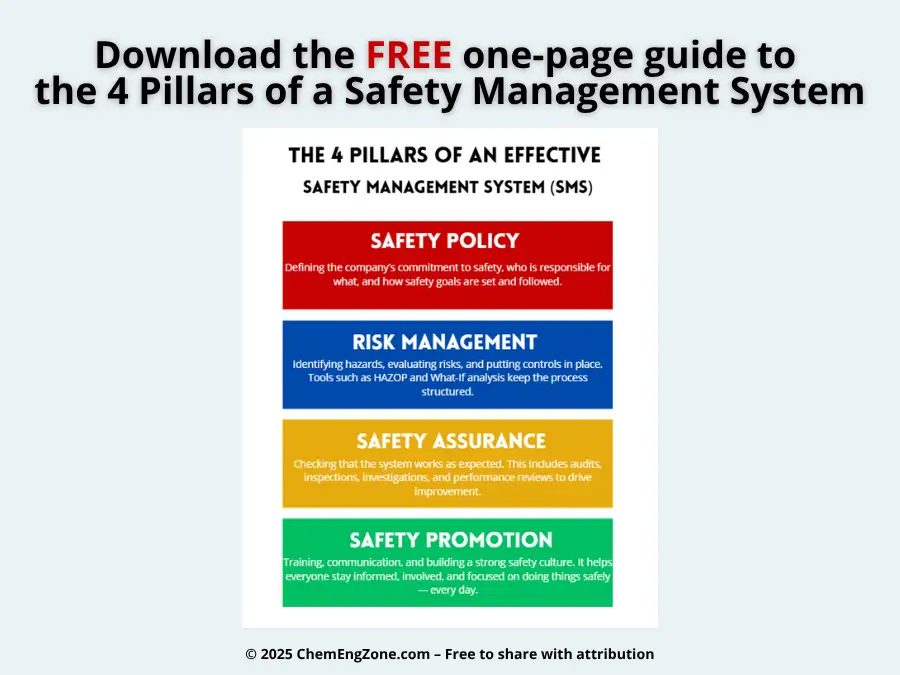

This visual summary outlines the 4 components of safety management system:

✅ Safety Policy – Objectives and responsibilities

✅ Risk Management – Hazard identification and mitigation

✅ Safety Assurance – Ongoing monitoring and improvement

✅ Safety Promotion & Culture – Communication, training, and safety values

Free Safety Resources for Chemical Engineers and Plant Managers

CCPS – Center for Chemical Process Safety

Access guidelines, incident case studies, and free tools from the AIChE’s CCPS, the global authority in process safety management.

European Commission – Seveso Directive Resources

Official documents, guidelines, and training material related to the Seveso III Directive and major accident hazard control in the EU.

OSHA – Process Safety Management (PSM)

Learn the key elements of PSM from the U.S. Occupational Safety and Health Administration, including legal requirements, FAQs, and accident reports.

UK HSE – Chemical Industries Guidance

Explore safety guidelines, incident prevention, and risk management material for chemical plants by the UK Health and Safety Executive.

Safety Case & SMS Guidance – IOGP

Download SMS framework guides and safety case development material from the International Association of Oil & Gas Producers (IOGP).

Process Safety Beacon

Subscribe for monthly 1-page process safety tips, designed for plant workers and engineers, with visuals and real incidents – free from CCPS.

FAQ

How to implement SMS pillars in chemical plants

To implement the SMS pillars in a chemical plant:

Set clear safety rules and assign responsibilities.

Identify risks using tools like HAZOP.

Track safety performance with audits and simple indicators.

Create a safety culture by training people and encouraging open communication.

Effective safety promotion activities

Short, daily safety talks, visible signage, employee recognition, and hands-on training are all powerful ways to promote safety. Consistent communication and visible leadership make a big difference.

What is the difference between Safety Policy and Safety Objectives?

The Safety Policy is a general commitment to safety — a guiding principle.

Safety Objectives are measurable goals that help put that policy into action.

Is the Seveso directive applied only in Italy or also abroad?

No — the Seveso Directive is a European Union law, so it applies in all EU member states, not just Italy. Each country implements it through national regulations, but the core principles (like hazard classification and major accident prevention) are shared across the EU.

What are the most common SMS mistakes in industry?

Failing to update procedures, poor communication, skipping audits, or treating safety as a one-time checklist instead of a continuous process.

Who is responsible for implementing the SMS in a plant?

Everyone plays a role, but leadership (plant manager, HSE manager) is responsible for structure, enforcement, and culture.