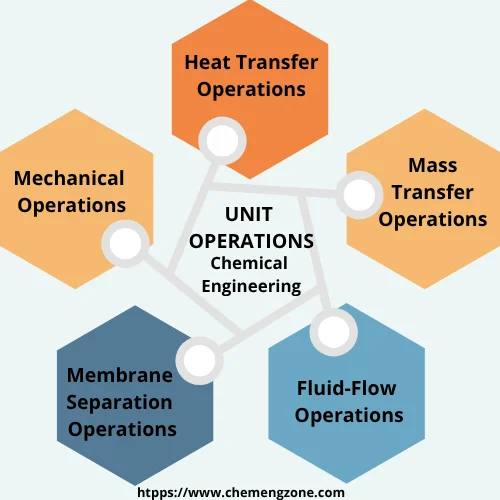

Unit Operations in Chemical Engineering

Unit operations are the building blocks of chemical engineering. They describe the fundamental steps involved in the transformation of raw materials into valuable products through physical changes such as heating, mixing, separating, and pressurizing.

Each operation—whether it’s heat exchange, mass transfer, mechanical handling, or separation—follows well-established principles and governing laws, allowing engineers to model, scale, and optimize industrial processes with precision.

Why It Matters

Unit operations are essential to designing and optimizing chemical processes. They turn theory into practical solutions used in real industries.

Unit Operations in Chemical Engineering

Essential heat, mass, mechanical & membrane unit operations for modern chemical-process design

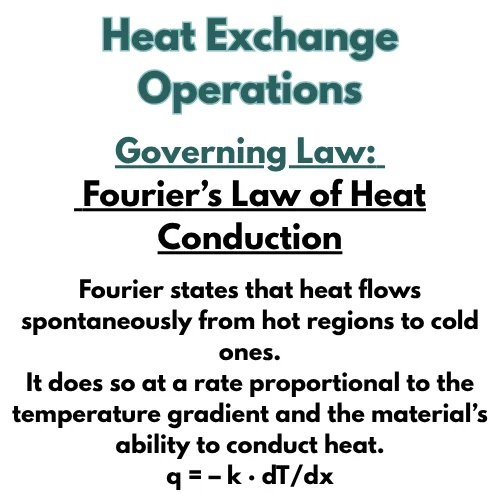

Heat Transfer

Heat transfer operations manage the flow of thermal energy from hot streams to cold ones to achieve target temperatures for reactions, separations, or utilities.

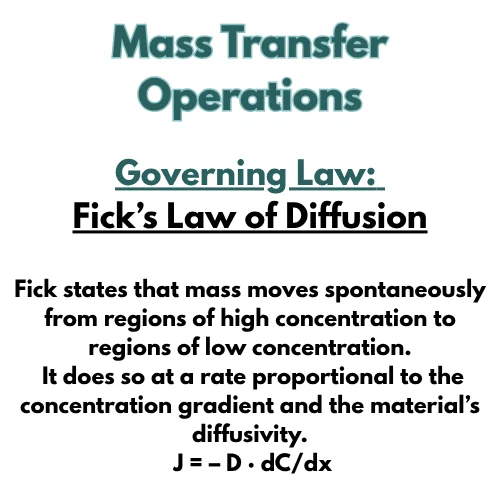

Mass Transfer

Mass transfer operations move species from one phase into another — gas to liquid, liquid to vapour, liquid to solid — whenever a concentration gradient exists.

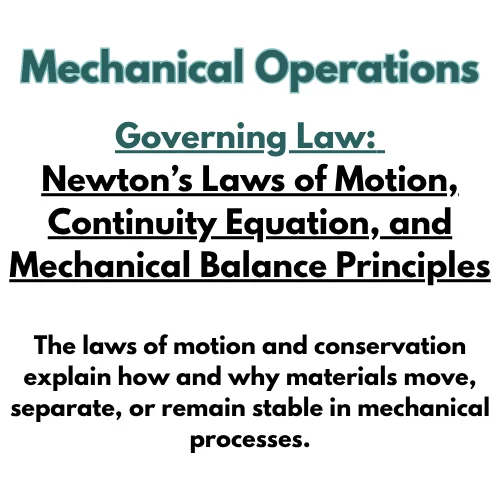

Mechanical Operations

Mechanical operations deal with the physical handling and transformation of solid particles and multiphase mixtures.

Membrane Separation

Membrane operations force fluids through semi-permeable barriers so that only selected molecules or ions-pass.

Fluid-Flow Operations

Fluid-flow operations manage the transport, distribution, and mixing of liquids and gases without changing their phase or composition. By sizing pumps, piping, valves, and static/dynamic mixers, engineers ensure that feeds, recirculation loops, and utility streams reach the correct vessels at the right flow rate and pressure.

Unit Operations – Technical Breakdown

In-depth guide to heat, mass, mechanical and fluid-flow processes in chemical engineering.

Key Heat-Exchange Operations

From simple tempering to vaporising column bottoms, heat-exchange steps drive energy efficiency and product quality across a plant.

– Sensible heating & cooling – raise or lower stream temperature without phase change.

– Boiling / reboiling – supply latent heat to distillation and flash systems.

– Condensation – recover vapours, enable reflux, cut solvent losses.

– Evaporation & concentration – remove water or solvents to meet spec.

– Cooling crystallisation – grow uniform crystals for pharma & food.

– Thermal insulation & heat-loss control – minimise unwanted heat flow on pipes, vessels, tanks to improve plant efficiency.

Key Mass-Transfer Operations

Mass-transfer steps separate and purify streams by moving species along concentration gradients.

Distillation – separate components based on volatility differences (vapor–liquid equilibrium, trays, packings).

Absorption – capture gaseous solutes into a liquid solvent (gas–liquid mass transfer, amine units, scrubbers).

Stripping – strip volatile or dissolved species from a liquid using a rising vapor (liquid–vapor mass transfer).

Liquid–Liquid Extraction – transfer solutes between two immiscible liquids (solvent extraction, mixer–settler, pulsed columns).

Leaching (Solid–Liquid Extraction) – dissolve and remove soluble compounds from a solid phase into a liquid solvent (metallurgy, biomasse, fanghi).

Adsorption – bind solutes from gas or liquid onto a solid adsorbent (e.g., carbone attivo, gel di silice).

Crystallization – induce formation of solids from a solution by cooling or evaporation (nucleation, crystal growth).

Key Mechanical Operations

Mechanical operations handle, transform, and separate solids (and slurries) to prepare streams for further processing. Click the links below for design guidelines and equipment selection:

Mixing – blend solids with liquids (slurries) or multiple solid fractions in ribbon blenders, paddle mixers, or high-shear mixers to create a homogeneous feed for separation or reaction.

Filtration – separate suspended solids from liquids by driving slurry through a porous medium (filter cloth, diatomaceous earth, or membrane), forming a solid cake that can be washed and discharged.

Sedimentation – allow particles to settle by gravity in thickeners or clarifiers; this concentrates solids and clarifies the overflow stream.

Decantation – gently remove the clarified liquid (or the settled solids) without disturbing the sediment, using weirs, pumps, or siphon devices.

Centrifugation – accelerate solid–liquid separation by applying centrifugal force in decanter or disc-stack centrifuges, achieving high throughput and fine-particle clarity quickly.

Screening – classify and remove particles by size with vibrating screens, trommels, or gyratory sifters to ensure a uniform feed.

Milling – break down large lumps into smaller particles using jaw crushers, hammer mills, or ball mills to achieve the desired feed size for downstream separation or reaction.

For a detailed study of crushing, filtration, sedimentation, and other motion-based operations, visit the NPTEL Mechanical Operations course offered by IIT. It covers fundamental principles such as Newton’s laws, the continuity equation, and mechanical balance in industrial applications.

Key Membrane Separation Operations

Membrane operations use semi-permeable barriers to separate components based on size or chemical affinity. Click the links below for design guidelines and flux/permeability charts:

- Microfiltration (MF) – removes particles (0.1–10 µm) and microorganisms from fluids. Common in wastewater polishing, food processing (e.g., milk clarification), and bioreactor harvest.

- Ultrafiltration (UF) – retains macromolecules (10,000–1,000,000 Da) such as proteins or polymers while passing water and small solutes. Used in protein concentration, cell harvest, and dairy fractionation.

- Nanofiltration (NF) – allows monovalent ions (Na⁺, Cl⁻) to pass but rejects divalent ions (Ca²⁺, SO₄²⁻) and larger organics. Employed for softening water, partial demineralization, and wastewater reuse.

- Reverse Osmosis (RO) – blocks nearly all dissolved salts, producing ultra-pure water. Essential for desalination, pharmaceutical water for injection, and semiconductor rinse water.

- Electrodialysis (ED) – uses an electric potential across alternating cation- and anion-exchange membranes to selectively remove ions from a solution. Ideal for brackish water desalinization, acid/base recovery, and dairy demineralization.

- Membrane Contactors – enable direct mass transfer between two phases (e.g., gas–liquid or liquid–liquid) without dispersing one into the other. Applications include CO₂ stripping from water, oxygenation of fermenters, and volatile solvent recovery.

Key Fluid-Flow Operations

Fluid‐flow steps move and control liquids and gases throughout a plant without altering their phase or composition.

Fluidization & Pneumatic Conveying – suspend solid particles in an upward gas or liquid stream (fluidized beds) or transport solids through pipelines using high-velocity gas flow (pneumatic conveying) for drying, coating, or material handling.

Pumping – transfer liquids from one vessel to another at required flow rates and pressures using centrifugal or positive-displacement pumps.

Pipeline Transport – convey fluids through networks of pipes and fittings, accounting for friction losses, elevation changes, and two-phase flow when sizing diameters and selecting materials.

Valve & Flow Control – regulate and throttle fluid streams using control valves, pressure-reducing valves, orifices, and flow meters to maintain stable process conditions.

Static Mixing – achieve homogeneous blending of two or more liquid (or gas) streams inline without moving parts, using insertion elements (e.g., helical, corrugated, or tab-type mixers).

Dynamic Agitation – mix reactants or slurries in tanks and vessels with agitators (propellers, turbines, anchors) sized by power number and Reynolds number to ensure uniform concentration and heat transfer.

Need reliable engineering references? Start with these.

Heat Exchangers: Operation, Performance, and Maintenance by Kuppan Thulukkanam (CRC Press, 2024) is a detailed reference for engineers dealing with thermal systems, boilers, and industrial heat exchangers. Covering in-service issues such as vibration, corrosion, fouling, non-destructive diagnostics, and maintenance, it offers practical guidance for performance monitoring and reliability in energy and process industries.

For engineers and students seeking a definitive technical reference on unit operations, Perry’s Chemical Engineers’ Handbook (9th Edition) remains an essential resource. Published by McGraw-Hill, this comprehensive handbook covers key topics such as heat and mass transfer, fluid flow, separation processes, mechanical operations, and process control—making it a trusted guide in both academia and industry.

Mass Transfer Operations for the Practicing Engineer by Louis Theodore and Francesco Ricci is a practical, example-based guide to core mass transfer operations—including distillation, absorption, stripping, and newer methods. Tailored for engineers in chemical, environmental, civil, and mechanical fields, it features solved problems, ABET-aligned topics, and PE exam tips—making it an essential resource for both industry work and certification prep.

FAQ

What is unit operation with example?

A unit operation is a basic step in a chemical or physical process that involves a physical change or transport, such as separation, mixing, heating, or cooling. In chemical engineering, complex industrial processes are broken down into multiple unit operations.

What is unit operation in pharmaceutical industry?

In the pharmaceutical industry, unit operations include critical steps like granulation, tablet compression, coating, and sterilization. Each operation ensures that the drug product meets quality and safety standards.

What is unit operation and unit process?

A unit operation involves physical changes (e.g., phase changes or mixing), while a unit process involves chemical transformations (e.g., reactions). For example, evaporation is a unit operation, while chlorination is a unit process.

What are unit operations in food processing?

Typical unit operations in food processing include pasteurization, emulsification, freezing, drying, and packaging. These operations are essential to maintain food safety and extend shelf life.